MES Polifemo - Integration and Operation

Principle of operation.

- System designed for integration or for "stand-alone" operation.

- The hardware structure provides for the use of a production Server as a data collector and multiple Client workstations (fixed or mobile), connected to an Ethernet network.

- Configurable system home page (Login) according to the user and the Client workstation used. Multilingual management.

- Master data: system (items, semi-finished products, bills of materials, raw materials, PNs, packaging, etc ..) and production (operators, machines, tools, tables with reasons for rejection and downtime, etc ..).

- Documentation (Jpg / Pdf): in the coding of the articles, possibility of associating images and photos (Jpg) or documents (Pdf).

- Technical Data Sheets: creation of processing sheets with machine parameters and technical production data, configurable and settable in relation to the machine-tool-article. Revision management and archiving.

Maximum and complete integration with existing company systems (Erp)

The system collect data from company ERP, such as, for example, personal data, orders, items, and returns the "products" to it, for the various stages of the process, for a timely alignment of the warehouses, both of raw materials and of semi-finished products and finished products. Where not possible, the system allows “stand-alone” management with local insertion of everything necessary for production. In Polifemo Xe, it is possible to associate images, photos, or documents to each individual item, which recall their shape and composition, or which facilitate online quality controls. There is also the complete management of technical and processing sheets, containing machine parameters and technical data, useful for production settings.

Production planning and scheduling.

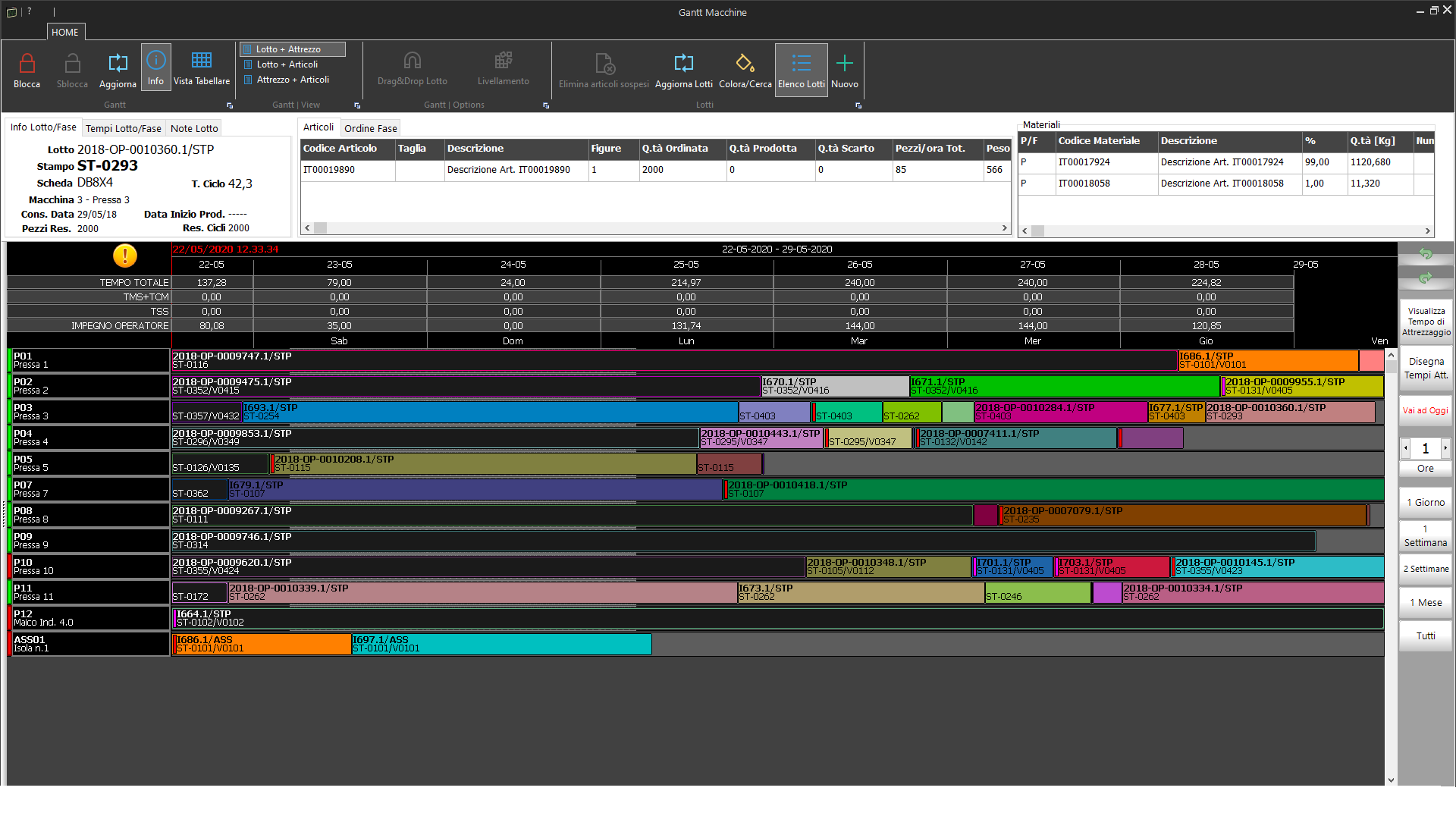

Planning: medium-long term verification of the workload on the different machines / departments (or groups of machines / departments); control of orders to be planned or already planned. Productive saturation analysis.

Scheduling: thanks to the use of the Gantt chart, intuitive viewing of the programming for each machine. Programming also possible for manual workstations or virtual machines.

Working calendars and shifts, settable and variable for individual machines.

Constant verification of the status of orders "created, planned, finished, packed, shipped".

Needs; calculation of material requirements, semi-finished products and "general or detailed machine" packaging. Picking Lists Management.

mail: info@itacasw.it

Phone: +39 0734.445279

Do you want to request more information or book a free demo?