MES Polifemo - Production Monitoring

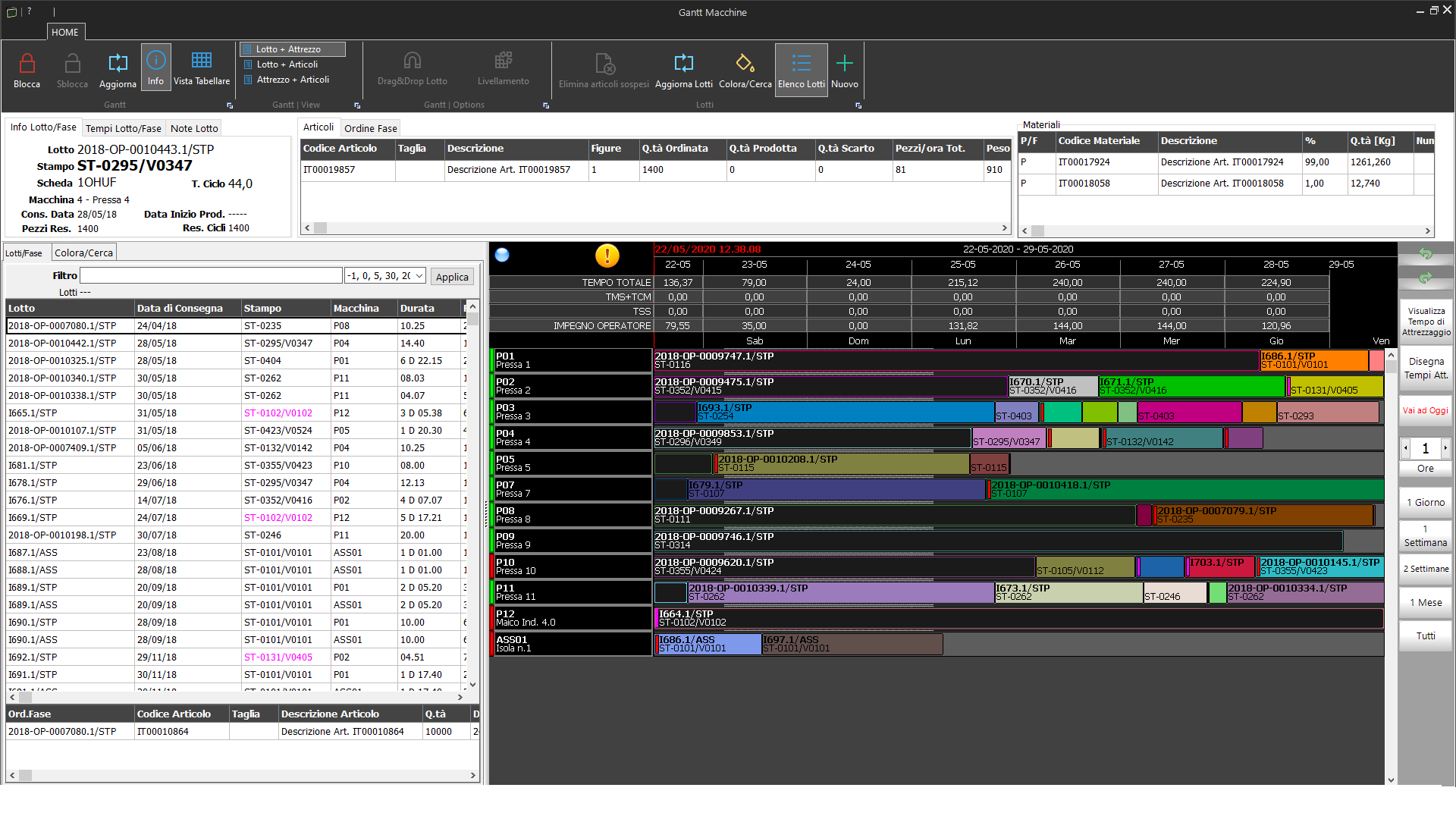

Production scheduling in Drag & Drop mode, using the Gantt chart.

With the Gantt chart, you have a quick, simple, and intuitive visualization of the programming by machine or work island, reducing errors, optimizing both the number of necessary resources and the related workload, and the set-up times. , start-up and change of production.

Each "brick" corresponds to an order or production batch. The schedule is updated in real-time, according to the actual progress of each individual order, thus checking compliance with the requested delivery date.

The programming phase is made simple thanks to the Drag & Drop mode, and takes into account the "settable and modifiable" working calendar, each individual machine or work island, machine downtime, tooling and any "alert" by interacting actively with the operator, preventing errors and promoting production optimization. Leveling can take place automatically, semi-automatically or manually, thus adapting completely to the various production needs and strategic business decisions.

The logic of the colors of the interface allows you to control the programming according to the criteria chosen by the operator, making the search immediate, by batch, article, order, material, etc.

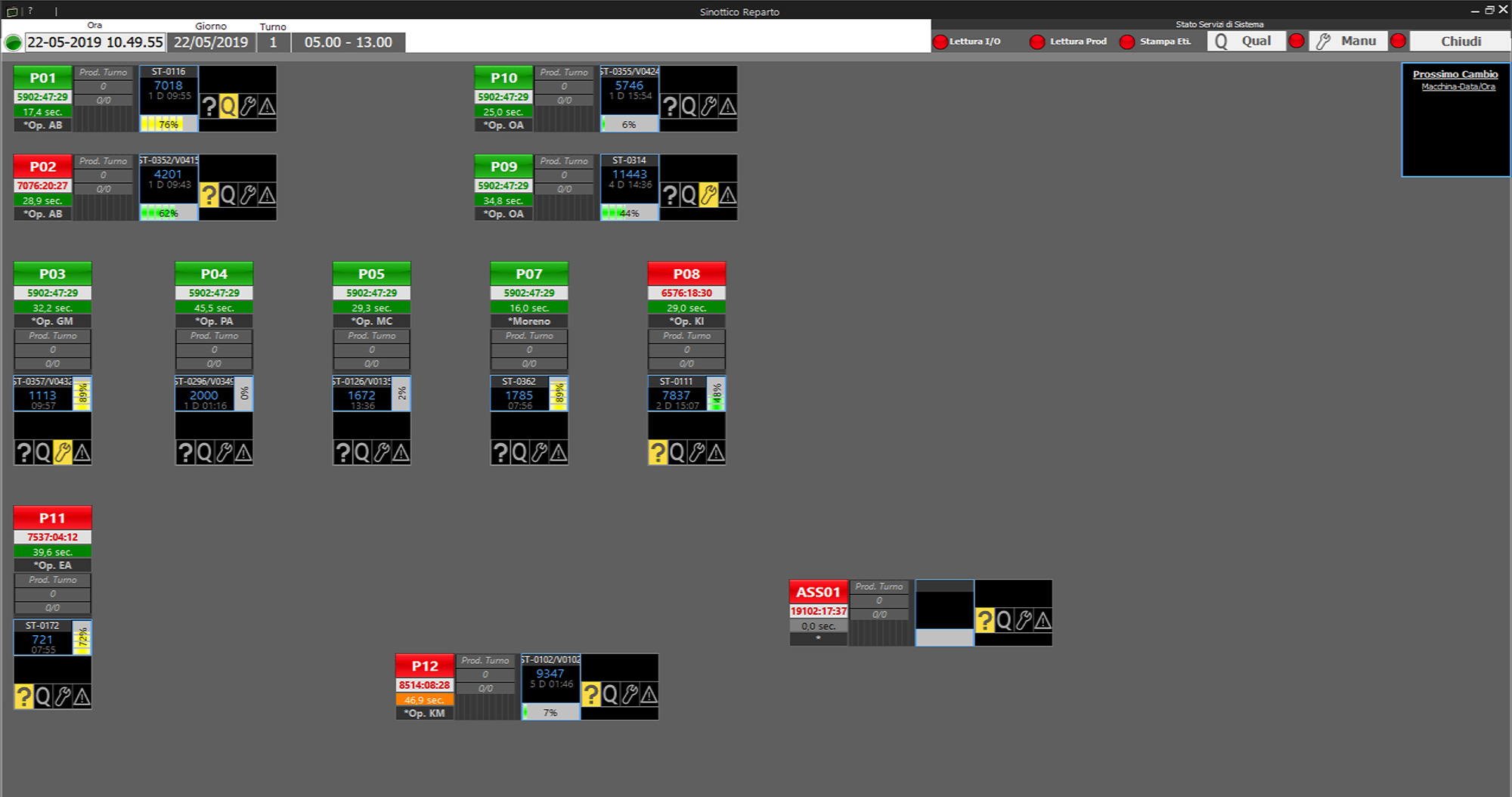

Real-time Production Monitoring. Department synoptic and machine synoptic.

Synoptic of Departments: allows the real-time display of the status of the machines and production progress, cycle times and assigned operators.

Automatic detection of signaling stops and alarm management for quality and maintenance checks, with request for operator intervention and causal association.

Machines connected to the system, via standard communication protocols (Opc, Euromap 63/77 etc ..), or via digital contacts to PLC panel / s.

Machine Synoptic: allows the visualization of the work cycle, stops on the shift, projection of the end of production, management of rejects and stops.

Production change, batch modification, possibility to change the number of cavities in the case of multi-cavity, assignment of raw material batches for traceability.

Possibility to view the technical data sheets with information on the working parameters of the machine or any further documentation.

Direct command for printing labels and processing cards

Quality controls and preventive and extraordinary maintenance with related document management.

Management of documentation in Pdf / Jpg format, to be displayed on the Client workstations, depending on the type of tool or item programmed in the machine. Also valid for manual workstations and virtual machines.

mail: info@itacasw.it

Phone: +39 0734.445279

Do you want to request more information or book a free demo?